Since 2008, ProTech Anodizing has been providing high quality, finished metal parts using a variety of processes to achieve the finish, look, and durability that is required for a job.

Our different types of Anodizing include:

Acid Etch

Anodizing

Flash

Anodizing

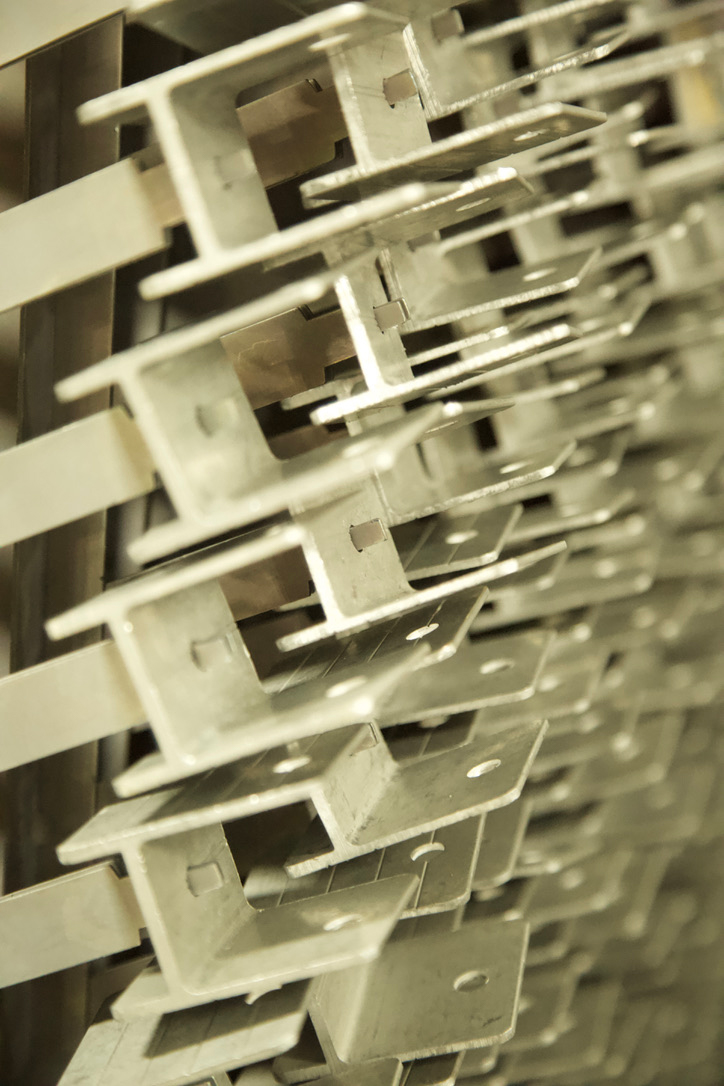

Small Parts Fabrication

and Tumbling

Custom

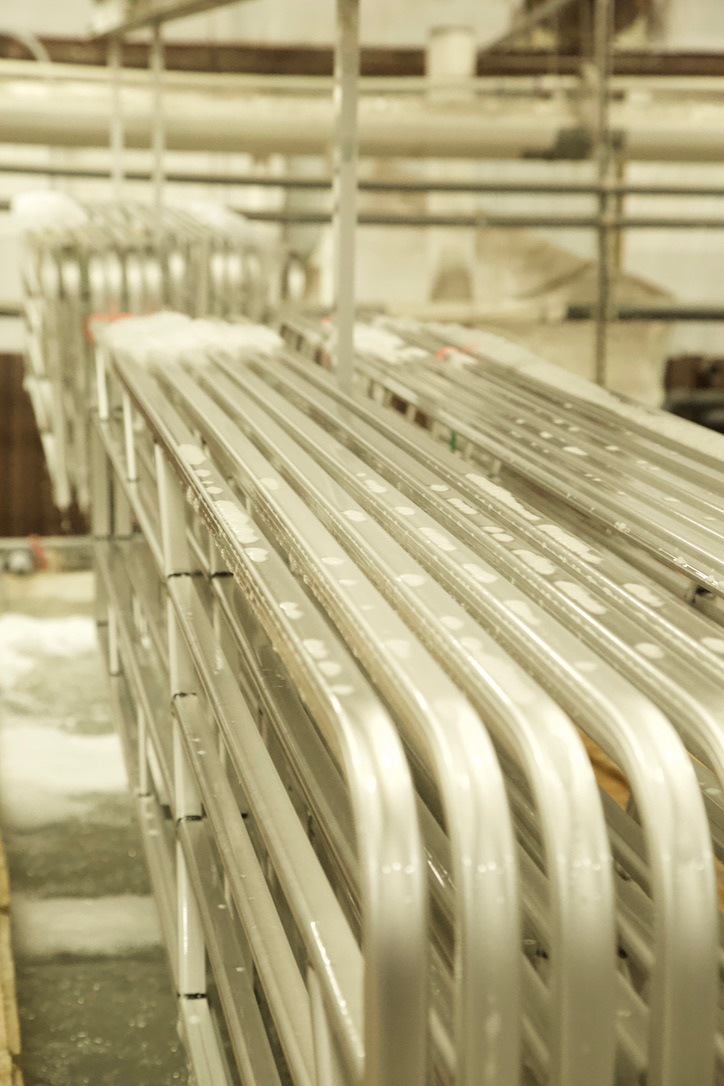

Racking

Full Electrolytic

Color Range

What is Anodizing?

Anodizing combines nature & science to develop one of the world’s greatest metal solutions.

Anodizing is the process of electrochemically controlling and enhancing oxidation of an aluminum substrate. The anodizing process produces an oxide film that is hard and protects the layer that is underneath the aluminum.

This provides incredible durability of our aluminum products and provides minimal maintenance throughout most environments including the marine, transportation, automotive, military, and architectural industries we serve.

How Does it Work?

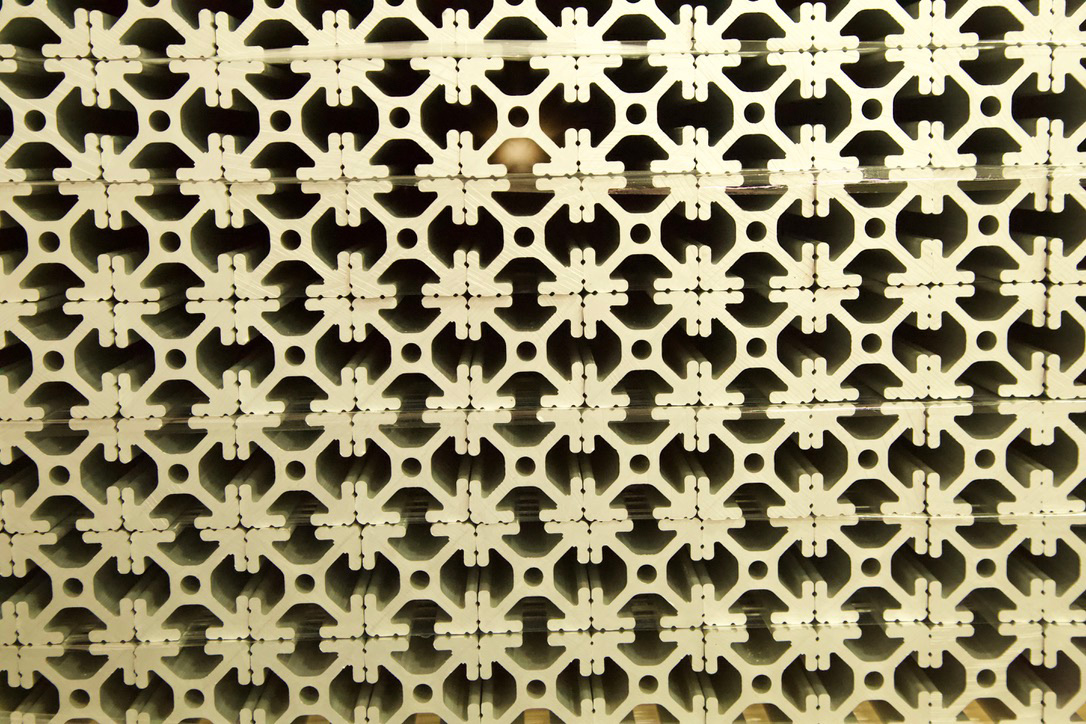

Anodizing is the process that takes a metal surface and converts it into a durable, reliable, decorative anodic oxide finish, which is what makes anodizing unique. Although aluminum is ideal for anodizing, other metals that have an insignificant amount of iron including magnesium and titanium also can be anodized.

The Benefits of Anodizing

Along with the massive benefits for the environment when anodizing aluminum or other non-ferrous metals, the unique anodized finish increases the lifespan and durability of any metals. Furthermore, anodization benefits include:

- Durability

- Color stability

- Ease of maintenance

- Cost efficiency

- Health and Safety

- Aesthetics